Interview with Marine Canvas Digital Patterning Expert:

Darren Arthur

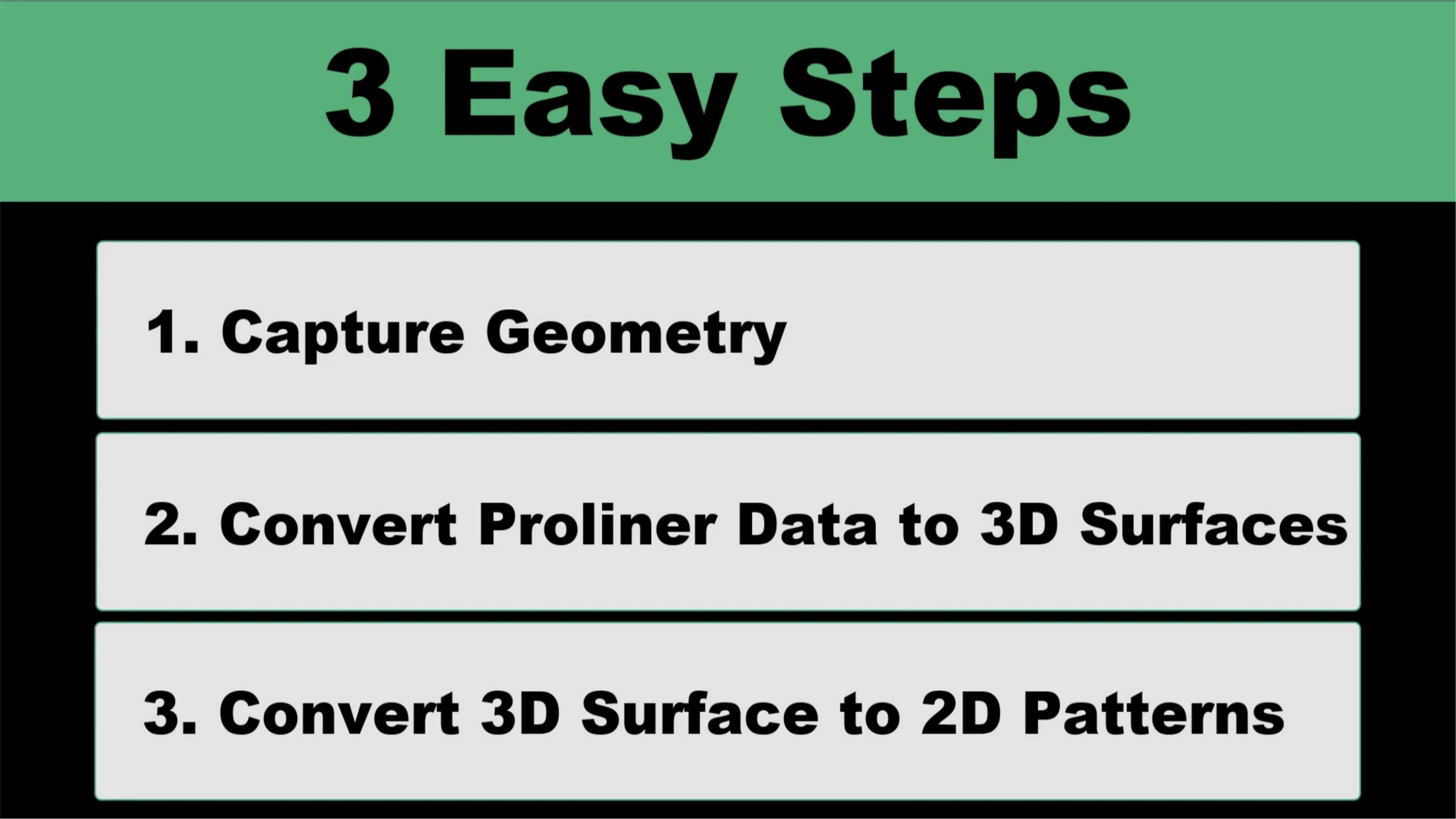

This interview reveals the deep transformation that Nautilux Canvas went through, when the company added technology to their pattern making process. Creating 2D patterns from 3D shapes with the help of ExactFlat for Rhino 3D, reduced the production time, created the opportunity to replicate models and reduced budget requirements. Darren Arthur recognized early on that without technologies, like improved scanning equipment (Proliner), 3D to 2D patterning (ExactFlat) or automated cutting, his business might have had a hard time surviving. As a pioneer of his industry, Darren Arthur has watched and assisted other companies adopting the essential technologies and improving and diversifying their services.

Table of Contents

Here’s the table of contents to the “Interview with Marine Canvas Digital Expert: Darren Arthur ” audio file. This video shows the major influence of technology in marine industry. Use the links below to navigate to the section of interest or watch the entire video:

0:00 Introduction

0:27 Company Overview

4:05 Technology in the Marine Industry

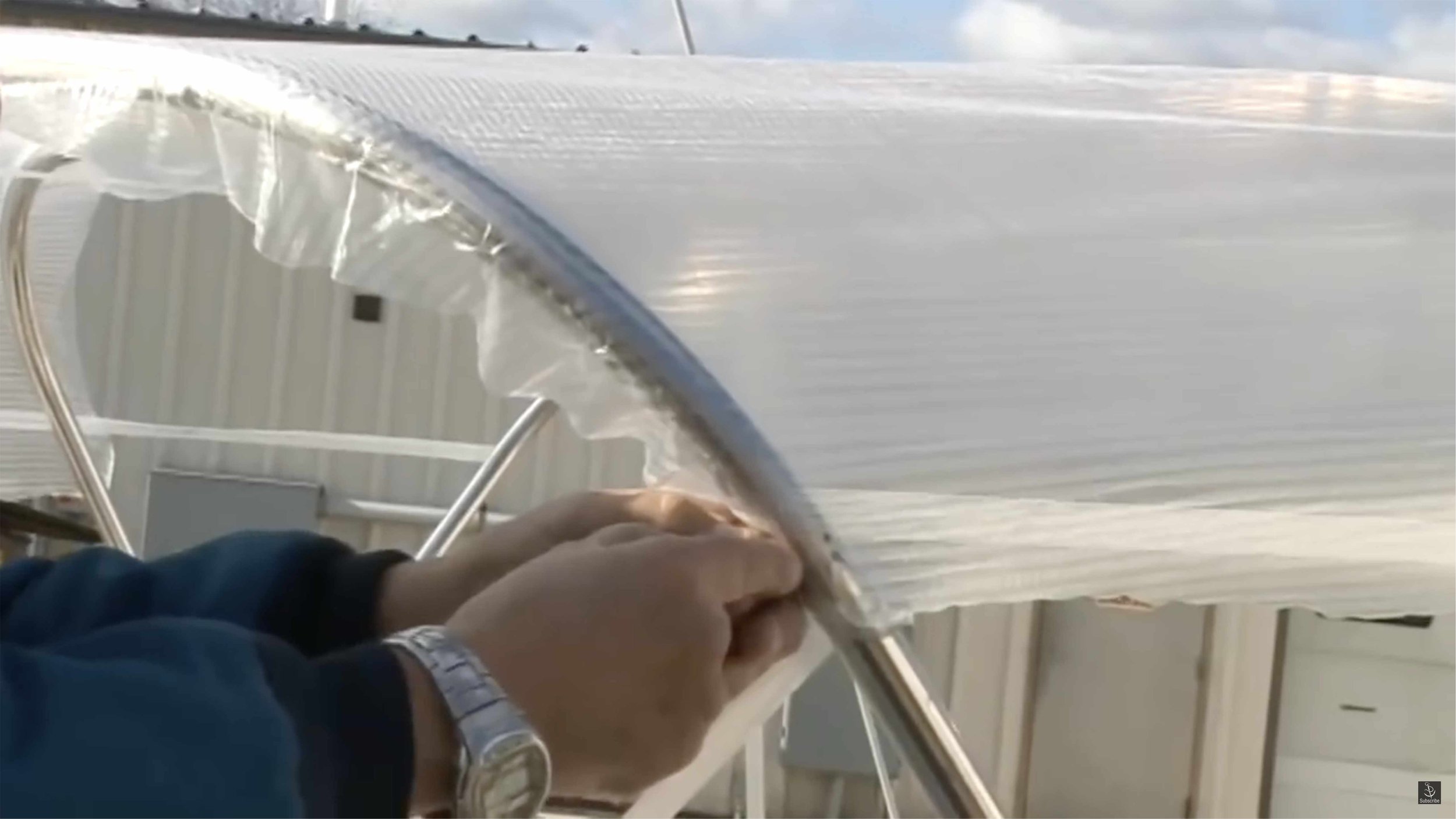

7:51 Traditional Methods of Patterning

9:02 Challenges of the Manual Patterning Process

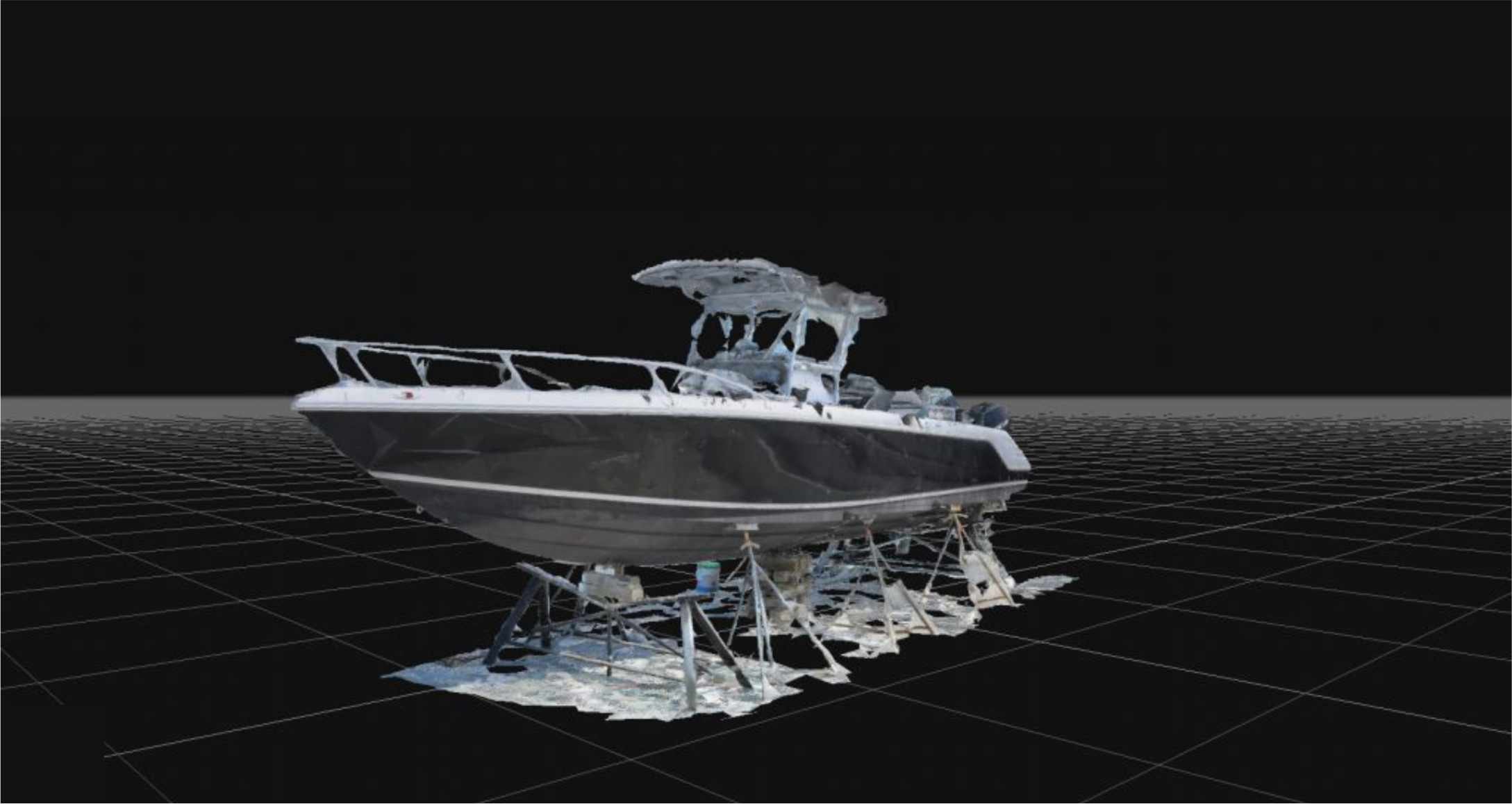

10:24 Photogrammetry

11:23 Material Usage

13:54 Manual Patterning to Digital Patterning

14:28 The Urgency of Using Technology

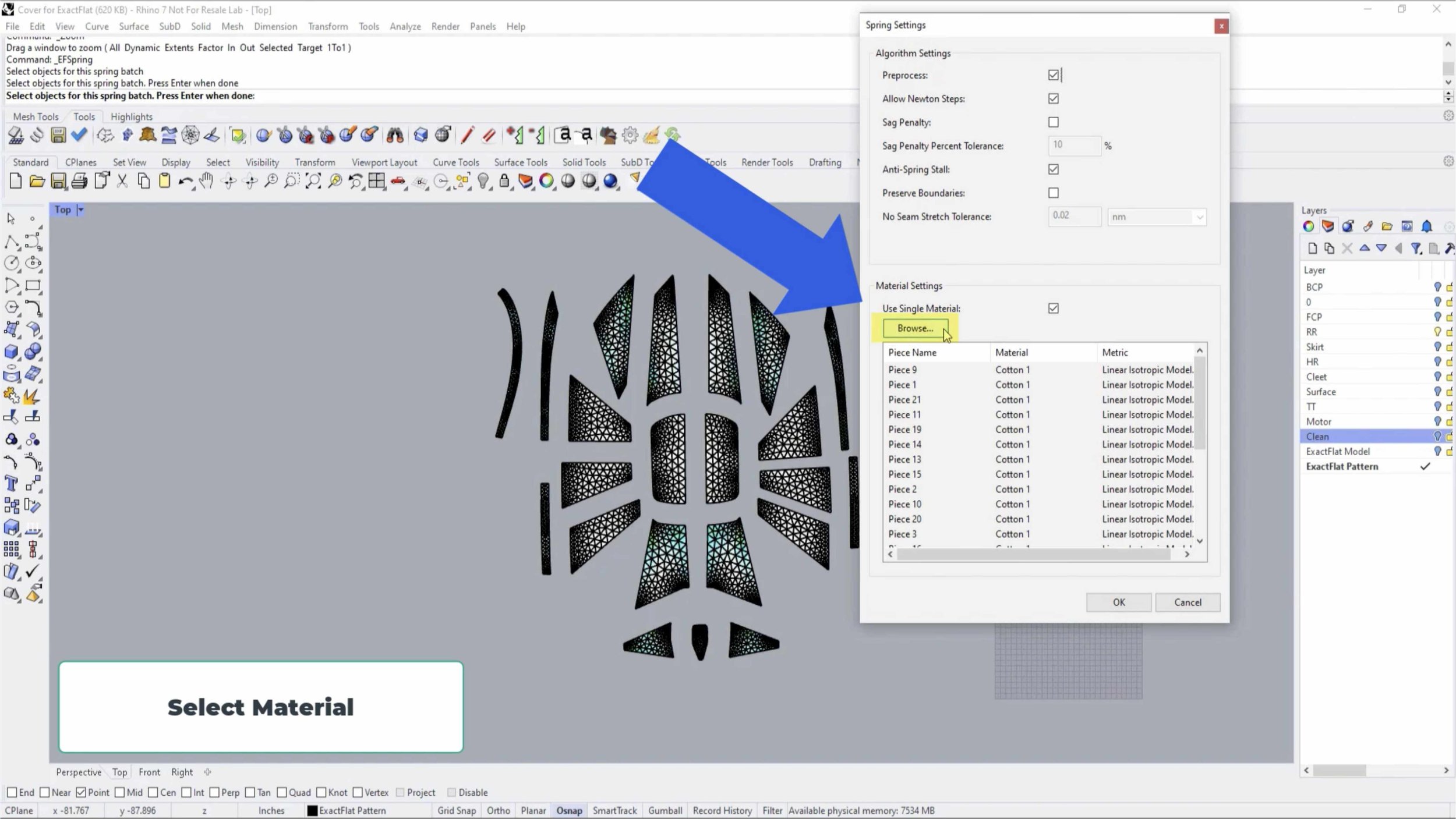

16:00 Bimmini Pattern

18:31 Manual Patterning Filing System

19:49 Production Standards and Technology

21:54 Production Efficiency

24:47 The "Flight Checklist"

33:06 Technology and Change

36:31 Technology Driven Service Development

38:58 Business Development

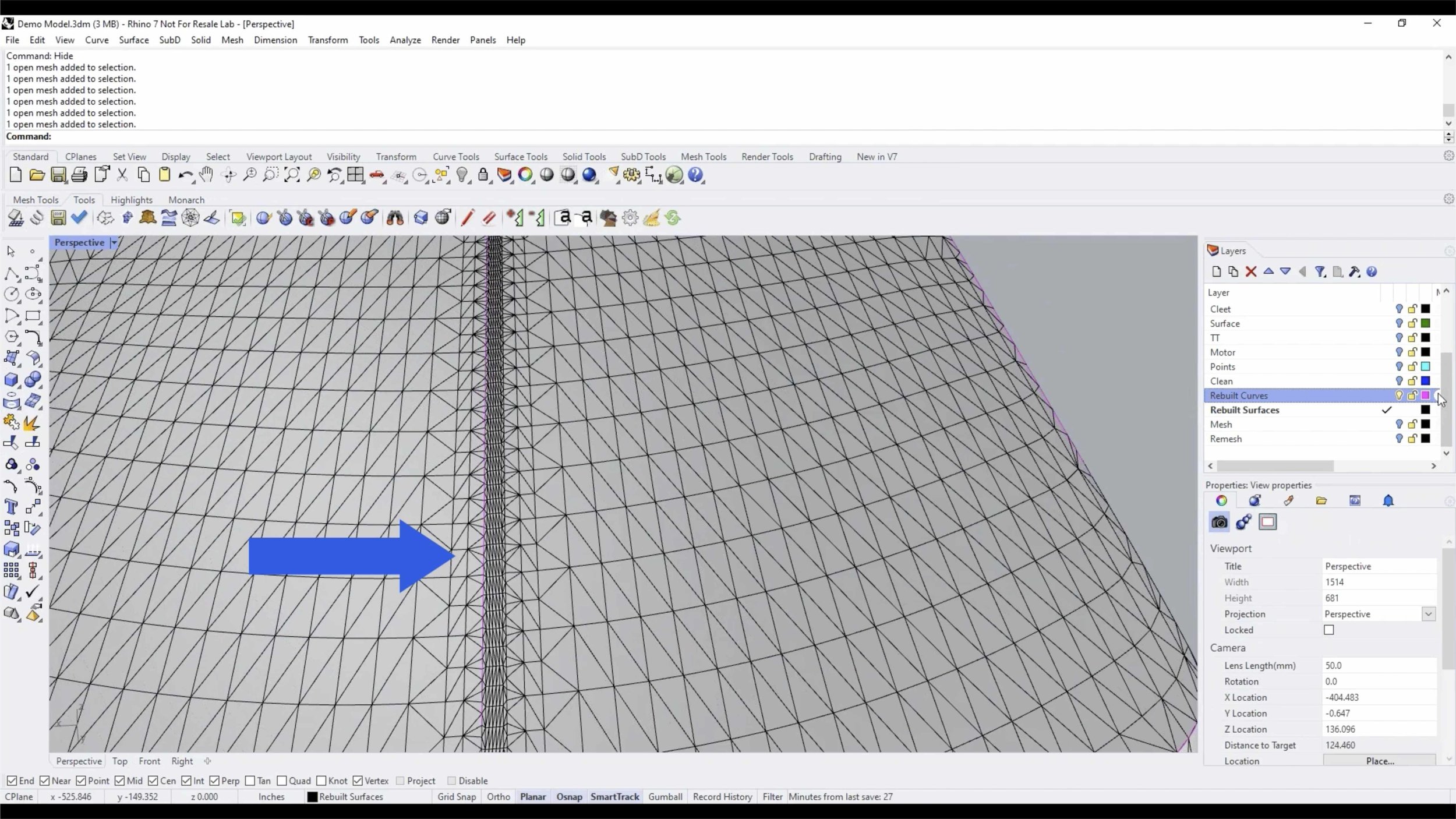

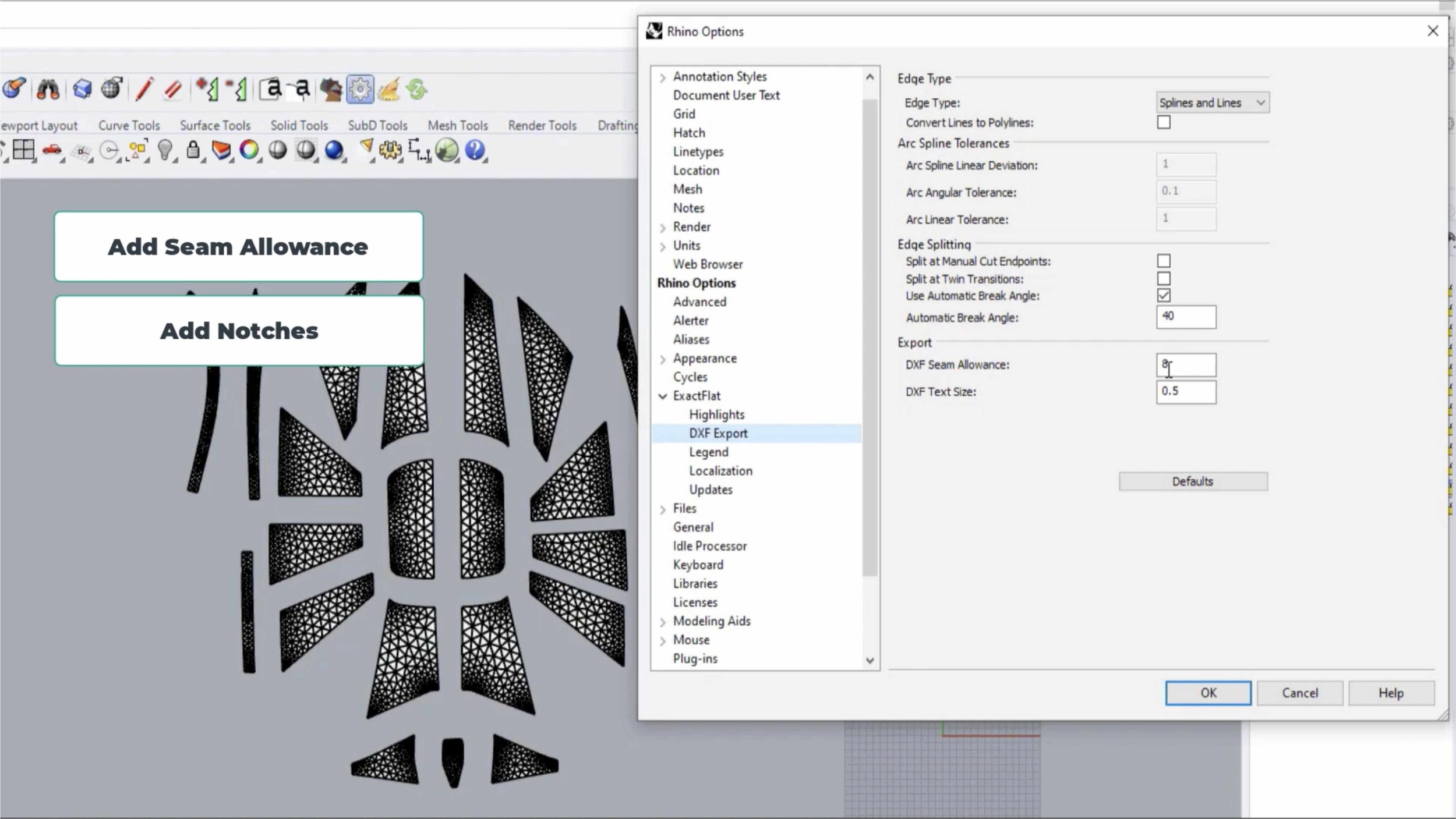

40:01 Digital Workflow

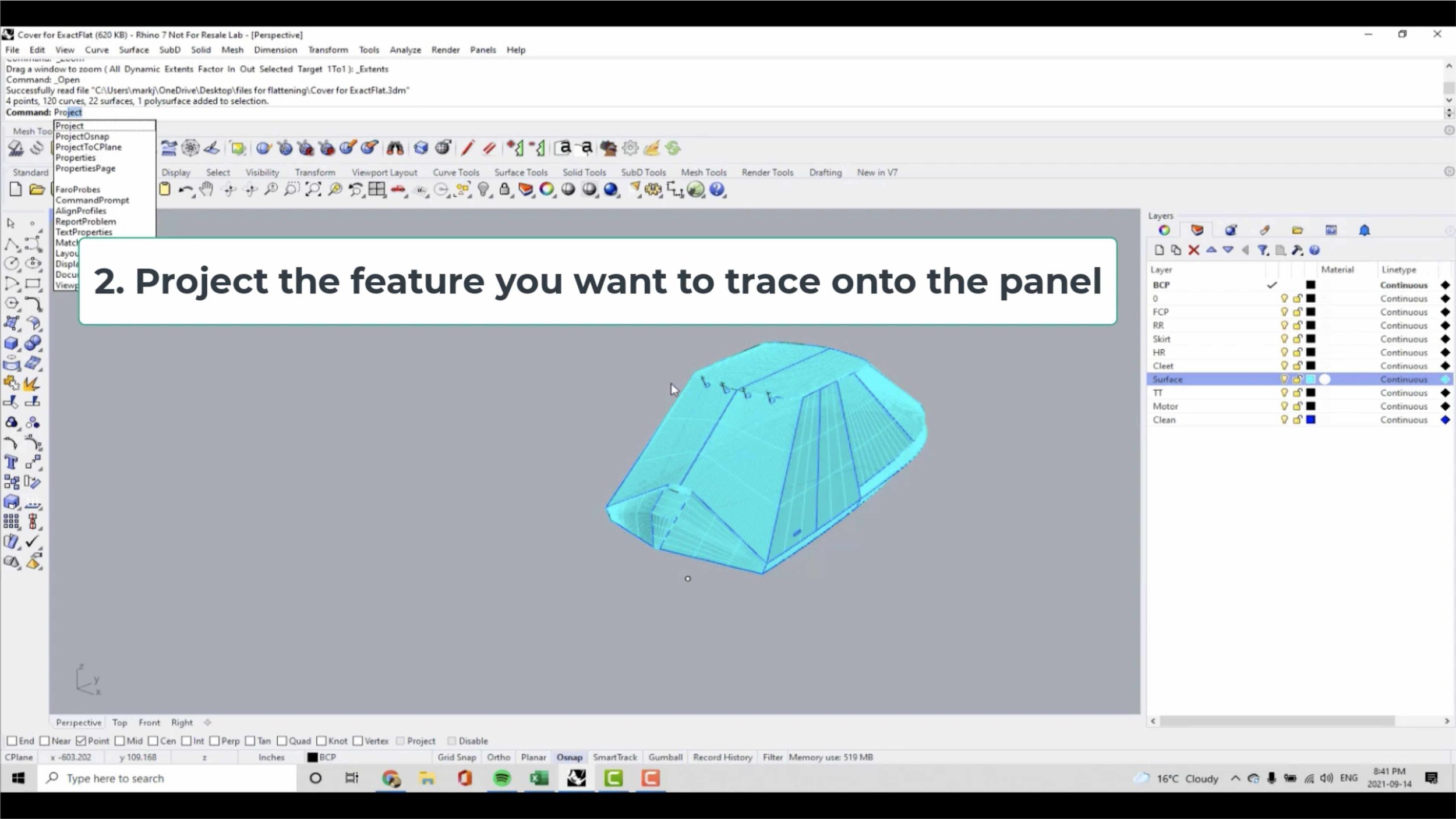

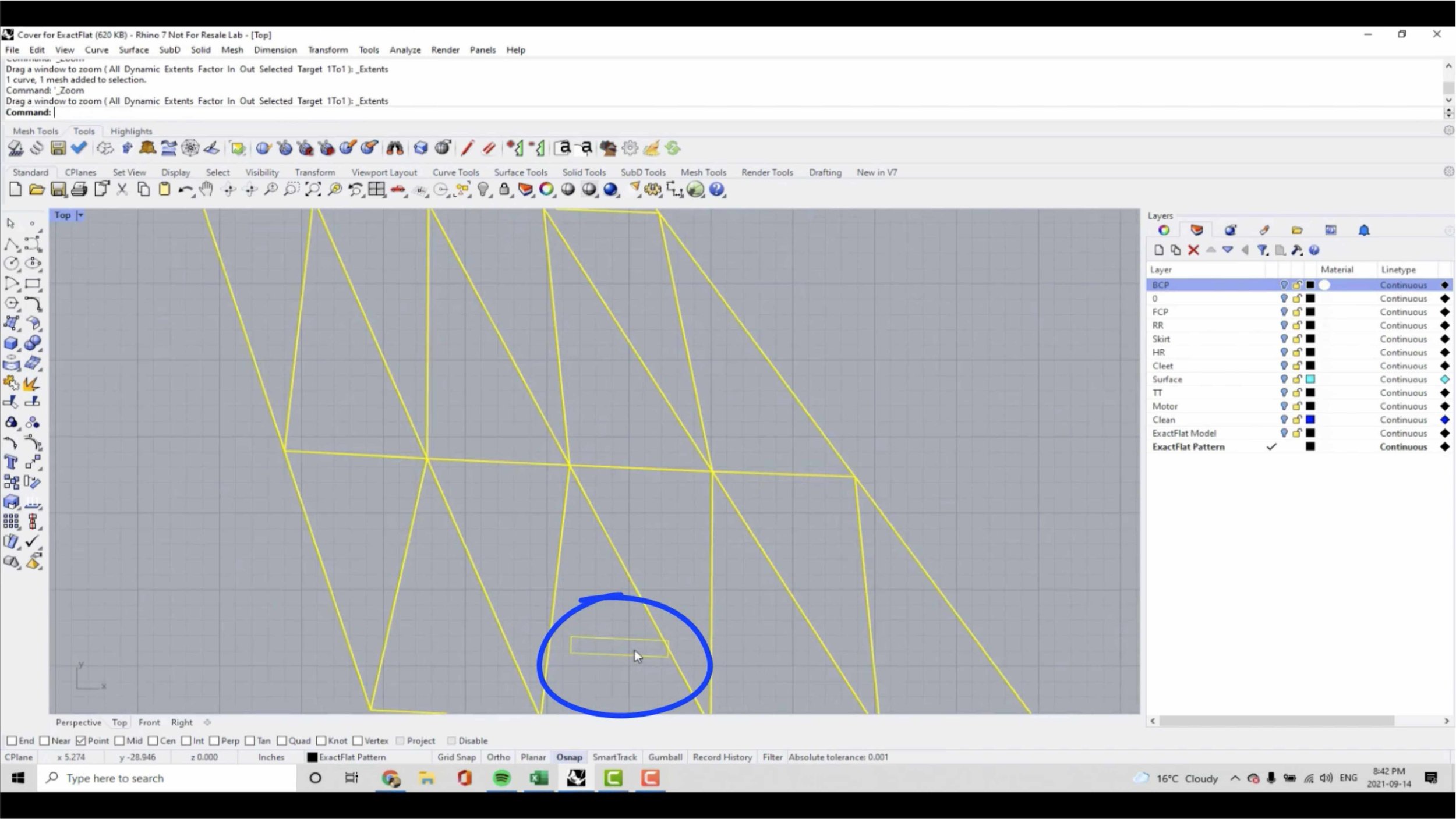

43:42 Scanning to 2D Pattern

51:23 Create a Framework

52:53 Create Scripts in Rhino

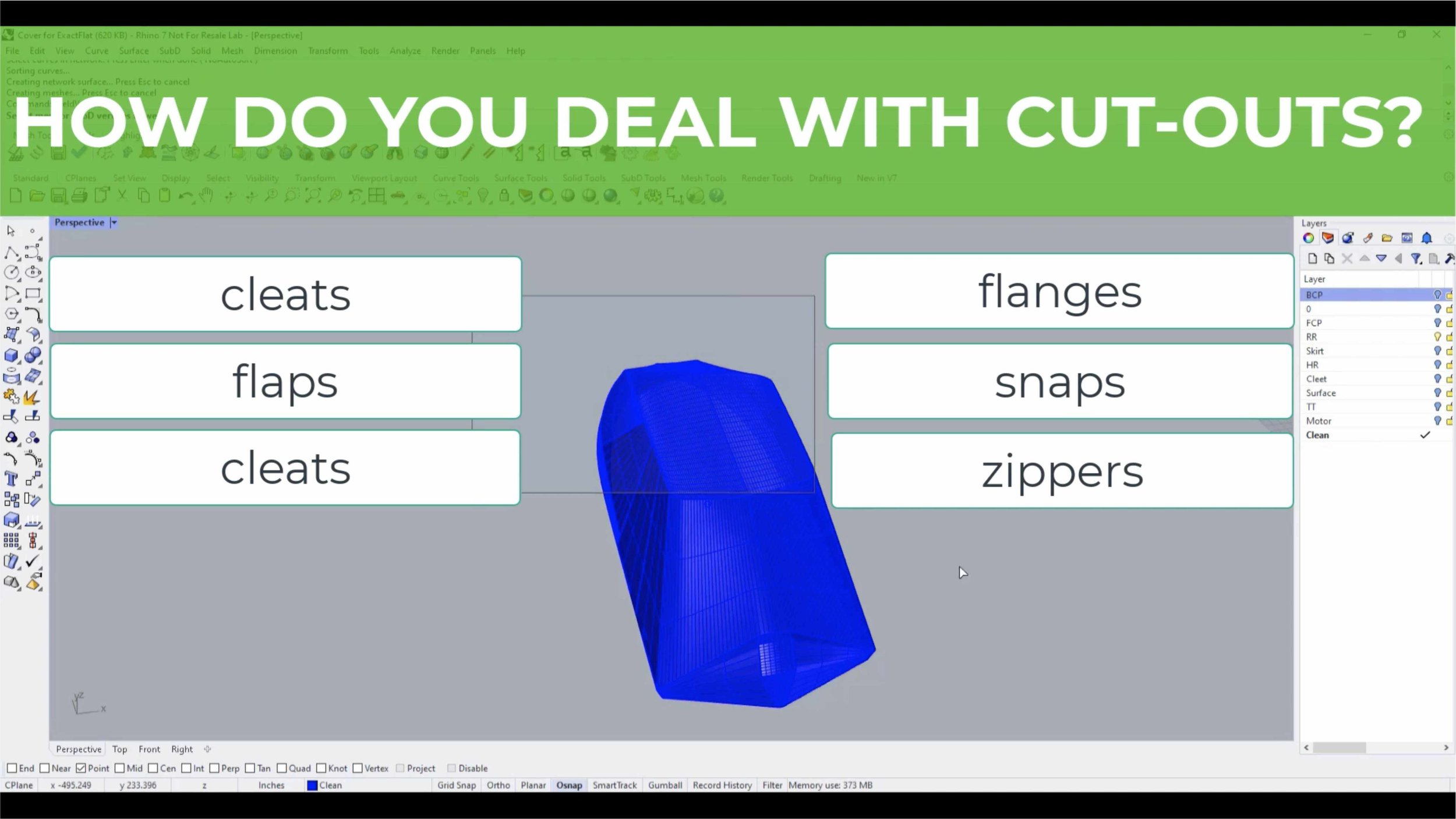

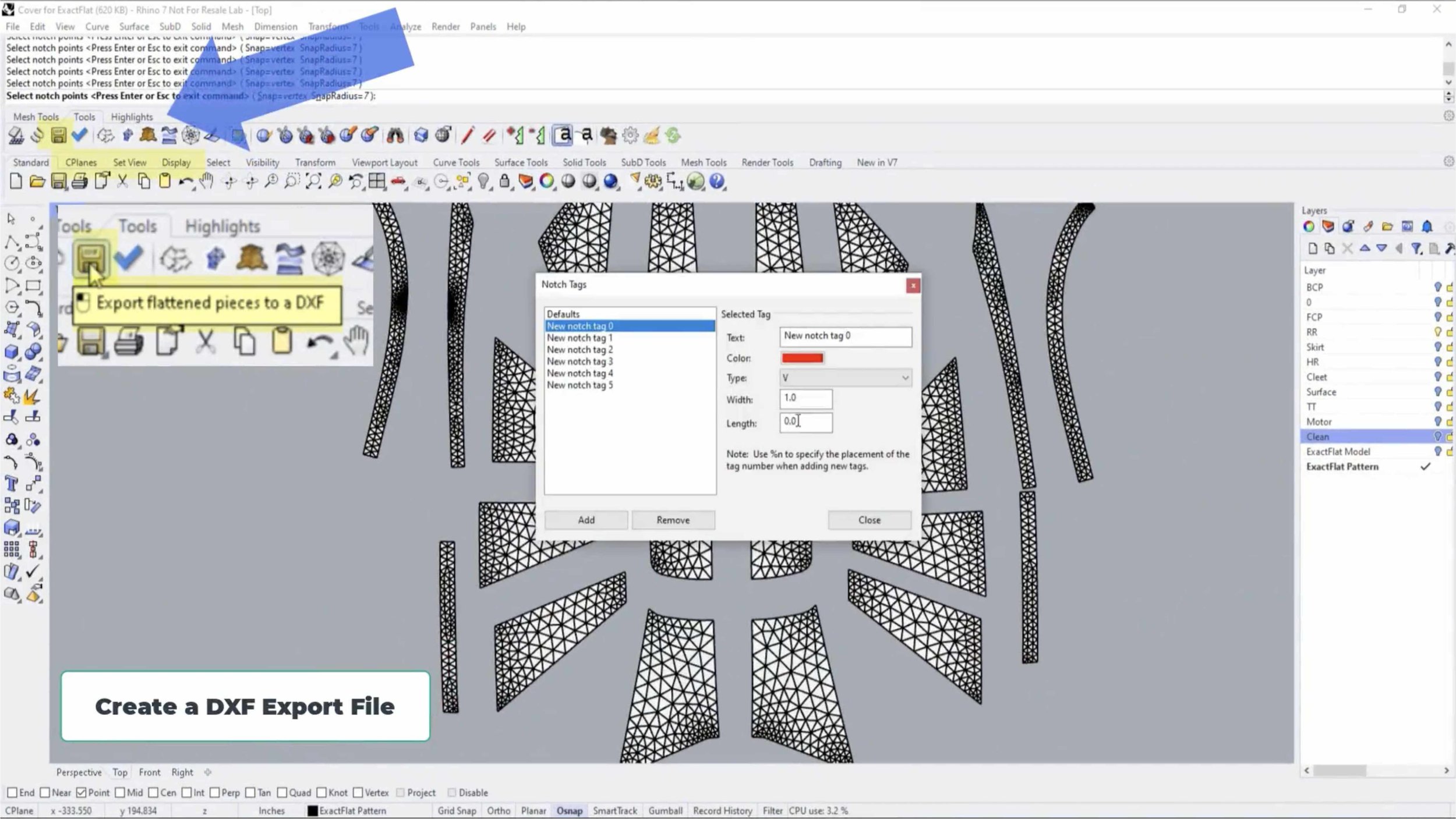

54:10 ExactFlat Functions

56:37 ExactFlat and Production Efficiency

57:33 Scripting Methodology

1:01:00 Process Documentation

1:03:32 Manual Patterning to Digital Patterning Revolution