ExactFlat for Rhino 3D is software for 3D to 2D digital pattern making

If you want faster, easier and more agile pattern making, 3D to 2D digital pattern making can help. ExactFlat works inside Rhino 3D so you can use Rhino supported file formats as input for creating 2D patterns for any type of product. There are 3 primary advantages to using 3D to 2D digital pattern making with ExactFlat.

First, ExactFlat is easy to use and easy to learn. Experienced Rhino 3D users can learn ExactFlat within 4 hours. For new users, we have courses focusing and the essential Rhino 3D tools, together with the ExactFlat workflow. This will help you complete your digital pattern making projects faster than you thought possible.

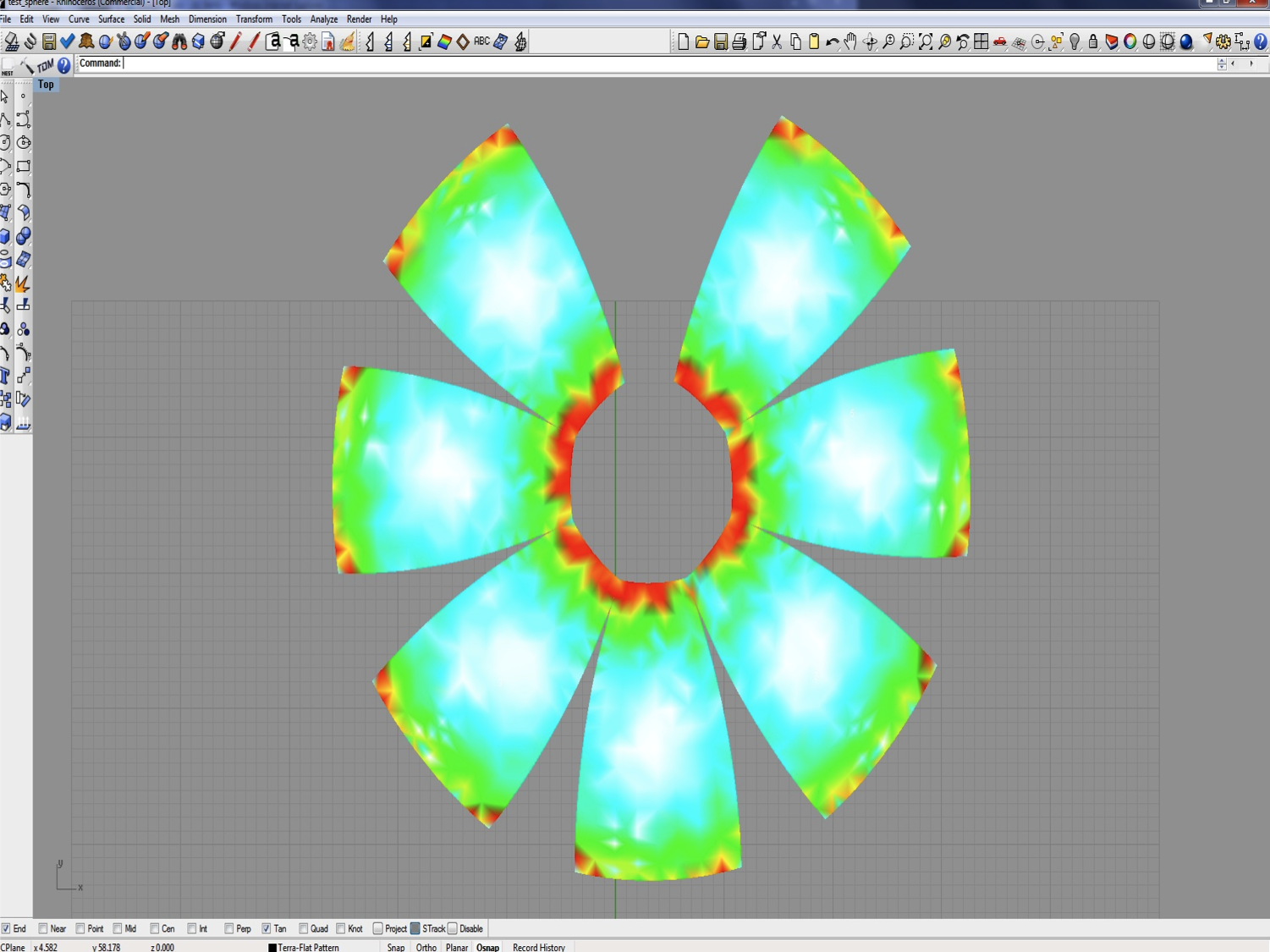

Second, ExactFlat has superior accuracy. This is because it is the only 3D to 2D digital pattern making software to take into account material properties and stretch characteristics. Superior 2D pattern making accuracy is also improved with adjustable target strain, mesh optimization, and 2 stage 3D to 2D surface flattening.

Lastly, ExactFlat is fast. Projects can be completed in minutes. This makes your pattern making, prototyping and costing more agile. Agility for more options. Agility for costing scenarios. Agility for better products

ExactFlat for Rhino3D helps your pattern making become faster, easier and more agile. If you want to give 3D to 2D digital pattern making a try, we’ll show you how.

Want to Learn 3D to 2D Digital Pattern Making?

We made a new 20 minute mini course on 3D to 2d digital pattern Making for you.

There are 19 very short sections, each from 30 secs to 90 seconds.

You can use this course to quickly understand the 3D to 2D digital pattern making workflow.

There is a video with chapters and a document with notes.

Click the button below to get the course.

ExactFlat 3D to 2D digital pattern making features include:

Design in Rhino 3D or import from laser scans or other 3D CAD packages.

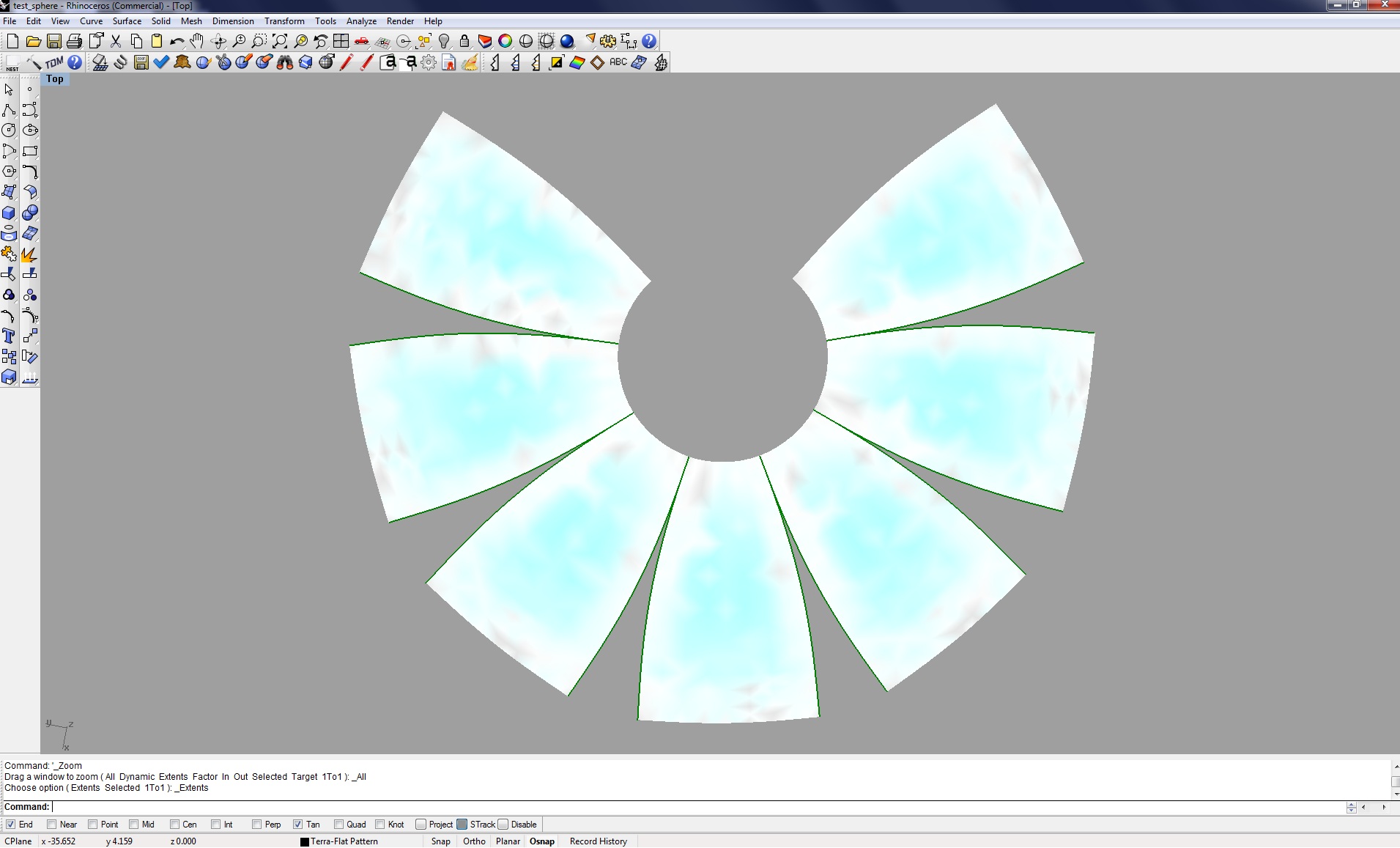

Accurately flatten double curved 3D surfaces into production ready 2D flat patterns.

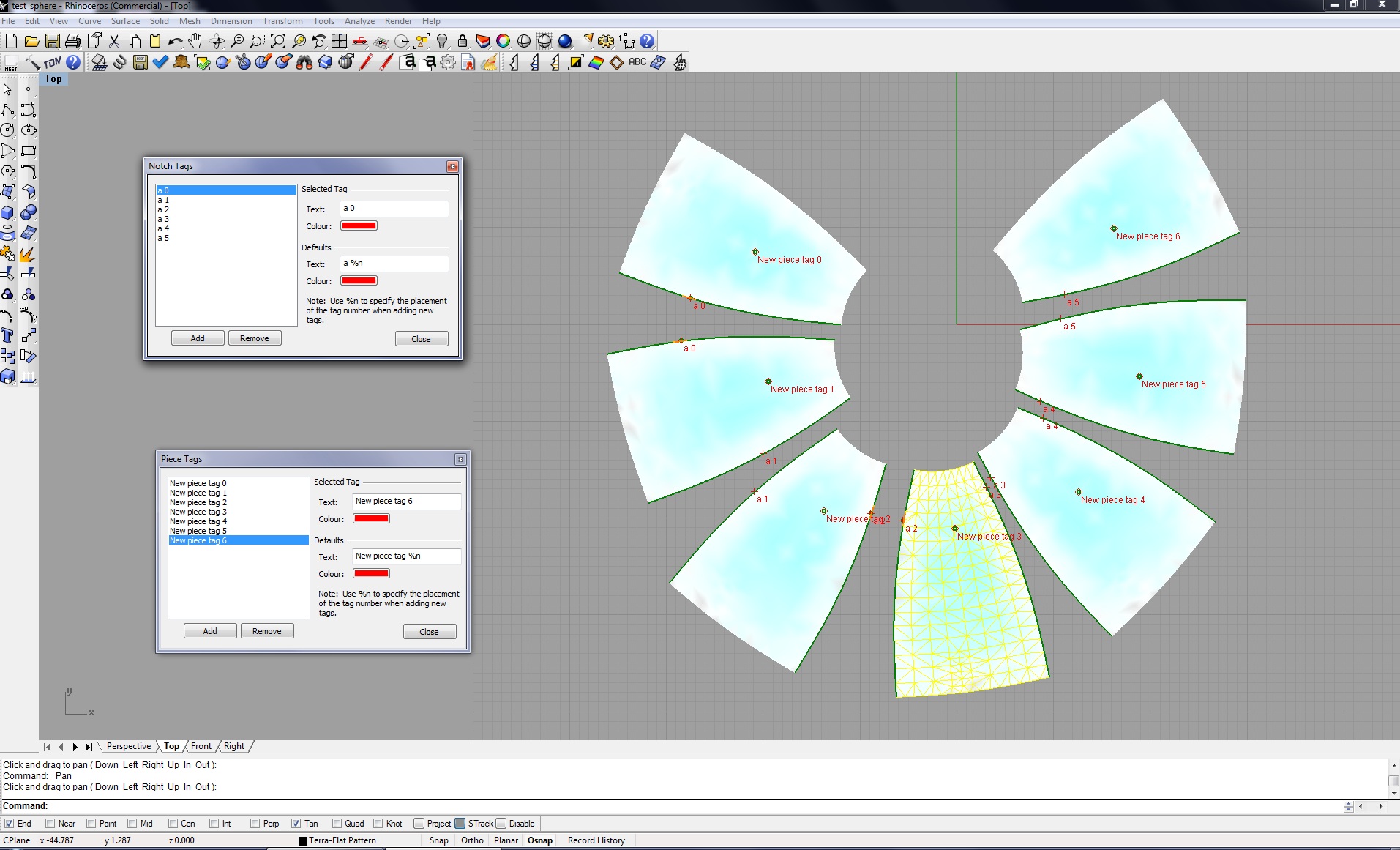

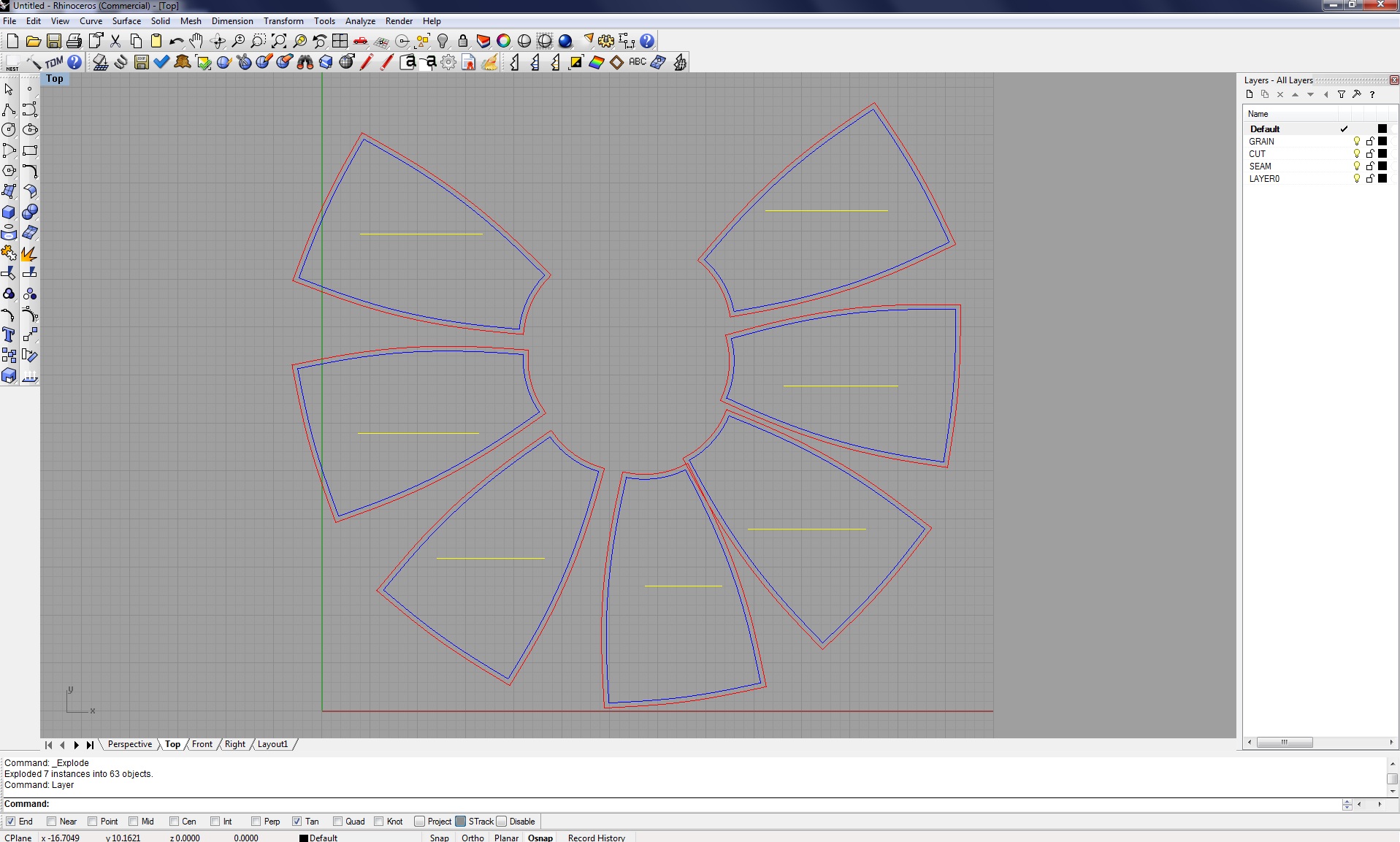

Add precision alignment notches, darts, seams and grain lines in seconds.

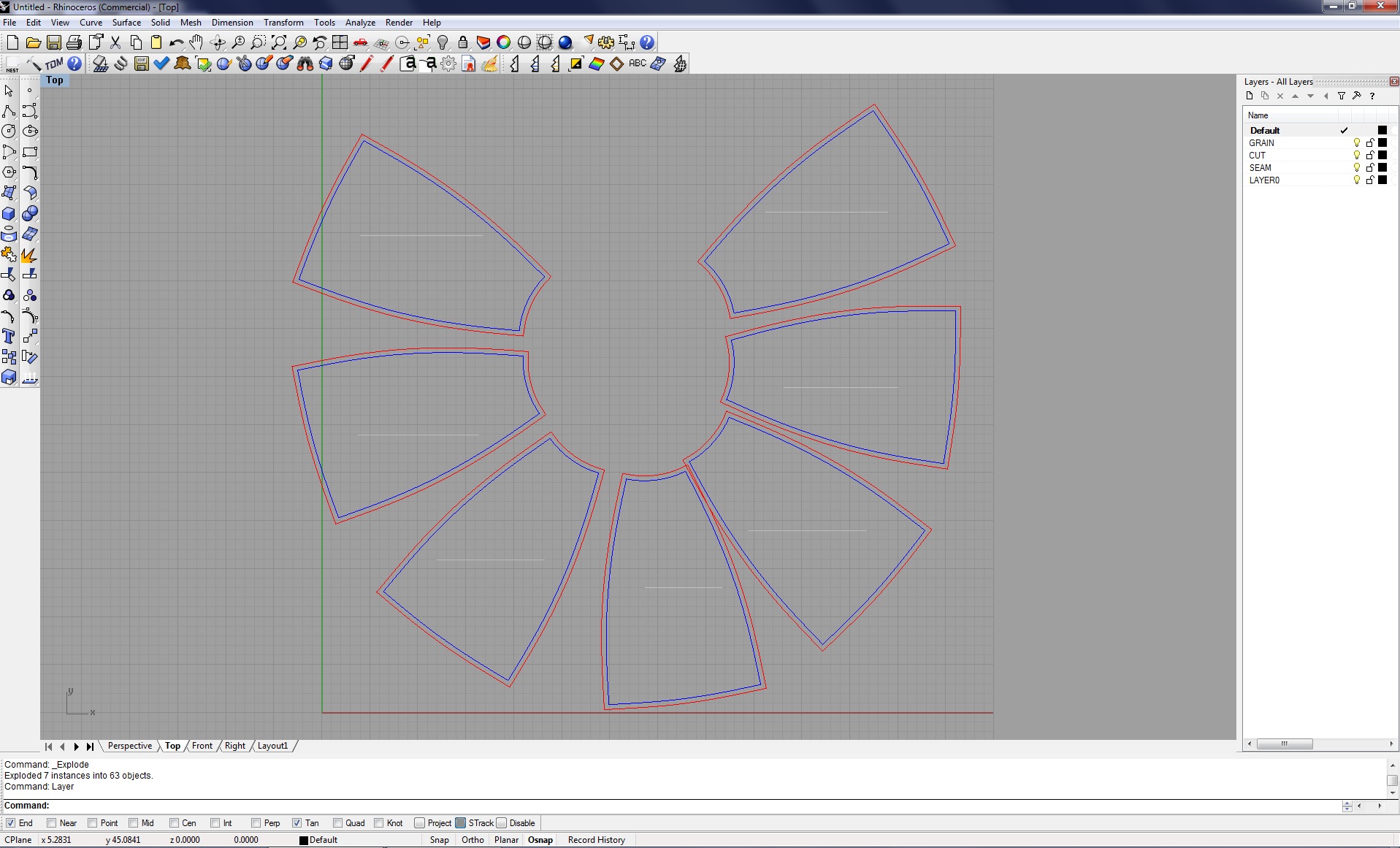

Export in standard DXF formats to create output for cutters or 2D fabric CAD packages.

To check out the full list of features click here

ExactFlat is for industrial soft goods and apparel

ExactFlat is for or designers, engineers, and pattern makers in all industries, including:

marine canvas and upholstery

furniture

automotive trim

paint protection film

inflatables

apparel

inflatables and aerospace

3D to 2D digital pattern making is up to 16x faster than hand patterning.

ExactFlat For Automotive Seating & Interiors (Example)

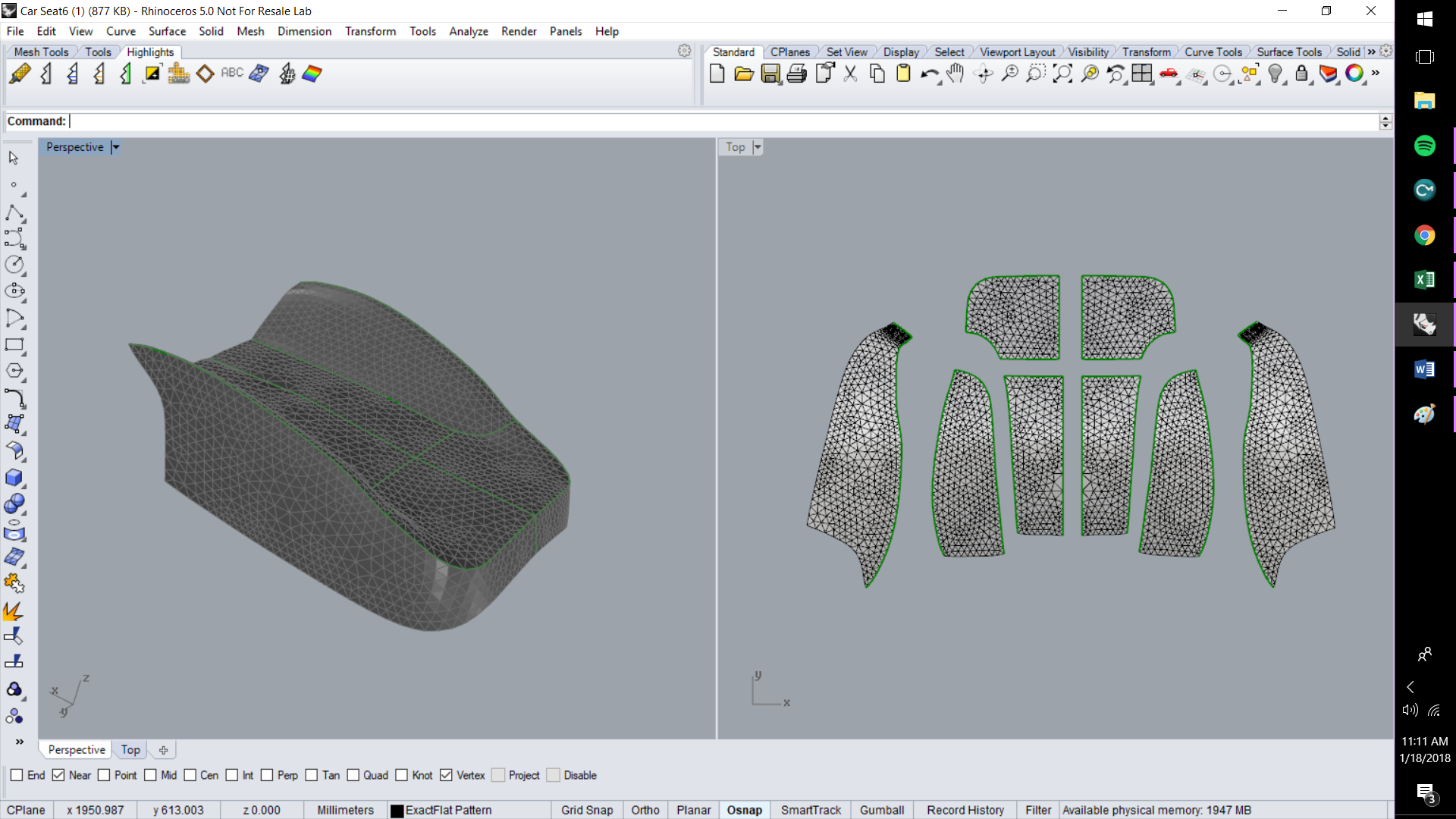

Automotive seat bun 3D model

shown in ExactFlat for Rhino 3D

Automotive seat bun 3D mesh with initial 2D flat patterns (before optimization) Shown in ExactFlat for Rhino 3D

Automotive seat bun 3D mesh Model

shown with strain map in ExactFlat for Rhino 3D

Automotive seat bun 3D mesh with strain map and initial 2D flat patterns (before optimization) shown in ExactFlat for Rhino 3D

Video Example ExactFlat for Automotive Seating and Interiors

The following video presents an example of using ExactFlat 3D to 2D digital pattern making for Rhino 3D on an automotive seat bun. Automotive interior components such as seating, center consoles, dashboards, steering wheels and door panels are excellent candidates for improving patterning with digital pattern making tools. This is because digital pattern making is faster and more agile, it works well with complex surfaces, and it is easy to learn and easy to use.

First, ExactFlat 3D to 2D digital pattern making offers a faster way to design and develop automotive trim patterns. The process can be completed in as little as 5 steps in 5 minutes with typical projects taking about 30 minutes to complete. The increased speed gives more time for optimization to produce a better product faster.

Second, ExactFlat can handle the 3D to 2D flattening of complex double curved surfaces. This is because ExactFlat can eliminate folds and wrinkles, optimize fit, and even apply a targeted amount of strain in areas where it is desired.

Lastly, ExactFlat can be learned in as little as 4 hours. Trim designers, and pattern makers are busy, and are under tremendous pressure to deliver results. Therefore ExactFlat has a simplified 3D to 2D workflow that maintains the conventions of the host CAD platform for easy and fast learning.

Automotive trim and seating pattern makers can benefit from understanding the digital patterning workflow. This video will show you an overview of the workflow so you can better understand the faster, more agile way to finish your projects.

ExactFlat Pattern Making For Rhino 3D Workflow is Easy to Learn

This Video demonstrates ExactFlat’s 3D to 2D digital pattern making work for Rhino 3D. It introduces the workflow and skills needed to become a successful pattern maker using 3D to 2D digital tools. Unlike other pattern making tools which can take weeks or months to learn, ExactFlat is easy to use and easy to learn. This is because: ExactFlat works within popular 3D CAD software, it uses a simplified workflow, and there is an abundance of schools, training centers, resellers, and trained professionals.

First, ExactFlat is easy to use because it works within two of the most popular 3D CAD programs - Solidworks 3D and Rhino 3D (this video relates to Rhino 3D). The interface and conventions of those tools are maintained within ExactFlat. Familiarity with these CAD programs means you can learn ExactFlat 3D to 2D digital patterning fast.

Second, ExactFlalt is easy to use because of its’ simplified workflow to go from 3D to 2D. The most common process involves 5 steps that can be completed in as little as 5 minutes. Most projects can be turned around in 30 minutes or less. This will make your pattern making agile and easy to learn.

Lastly, ExactFlat is easy to learn because there is a massive ecosystem of trained 3D CAD users in addition to a widely distributed network of training options to learn these 3D CAD programs. For users familiar with 3D CAD, it usually takes no more than 4 hours to learn ExactFlat because many of the conventions are similar to those in 3D CAD. Unlike other software, you can get trained and find trained people faster.

To see the full 3D to 2D digital patterning process for yourself watch the video below.

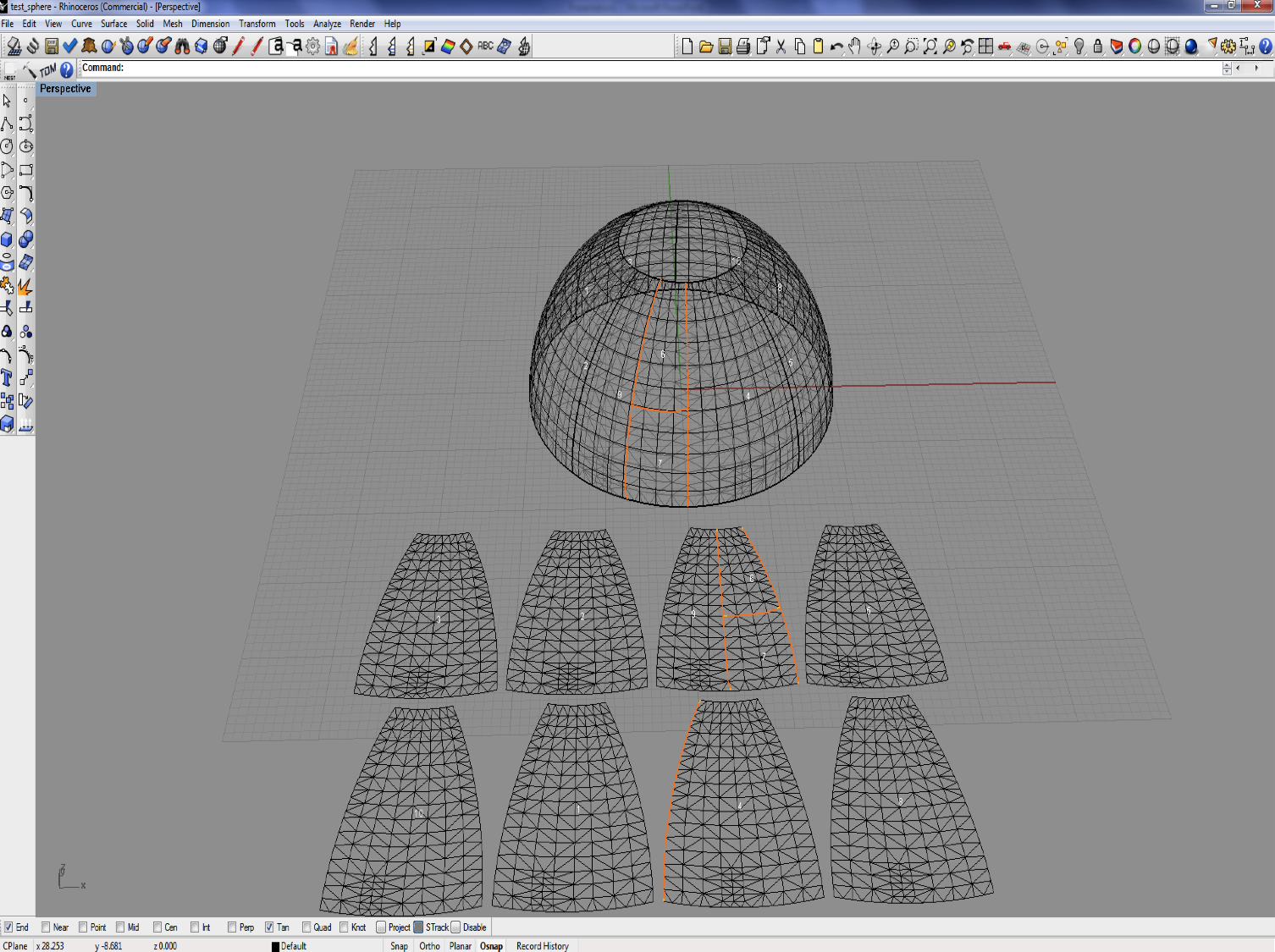

3D to 2D Flattening and Digital Pattern Making Gallery

3D TO 2D PATTERN MAKING IMAGE GALLERY SHOWING A SPHERE AND AUTOMOTIVE HEADREST

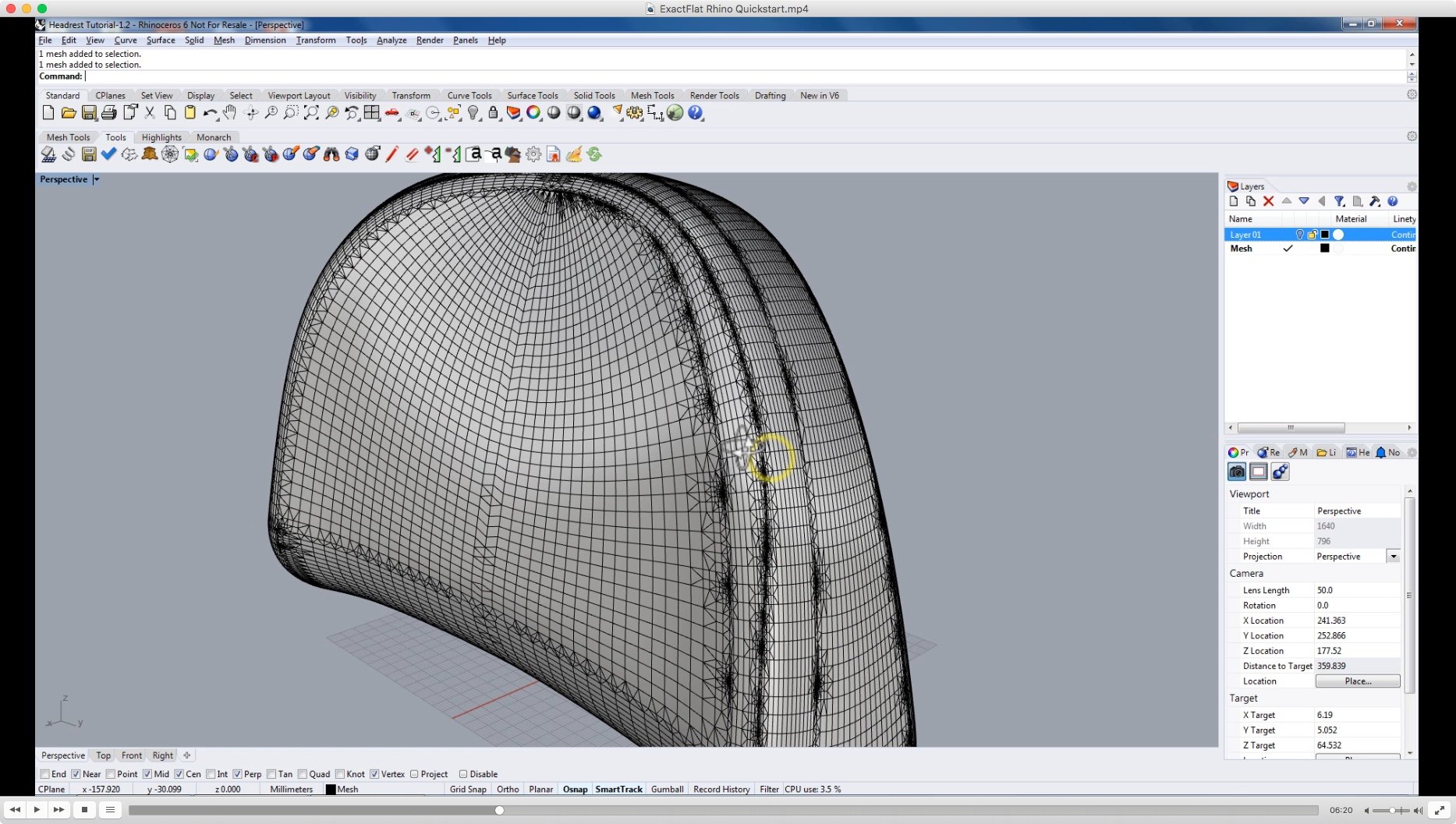

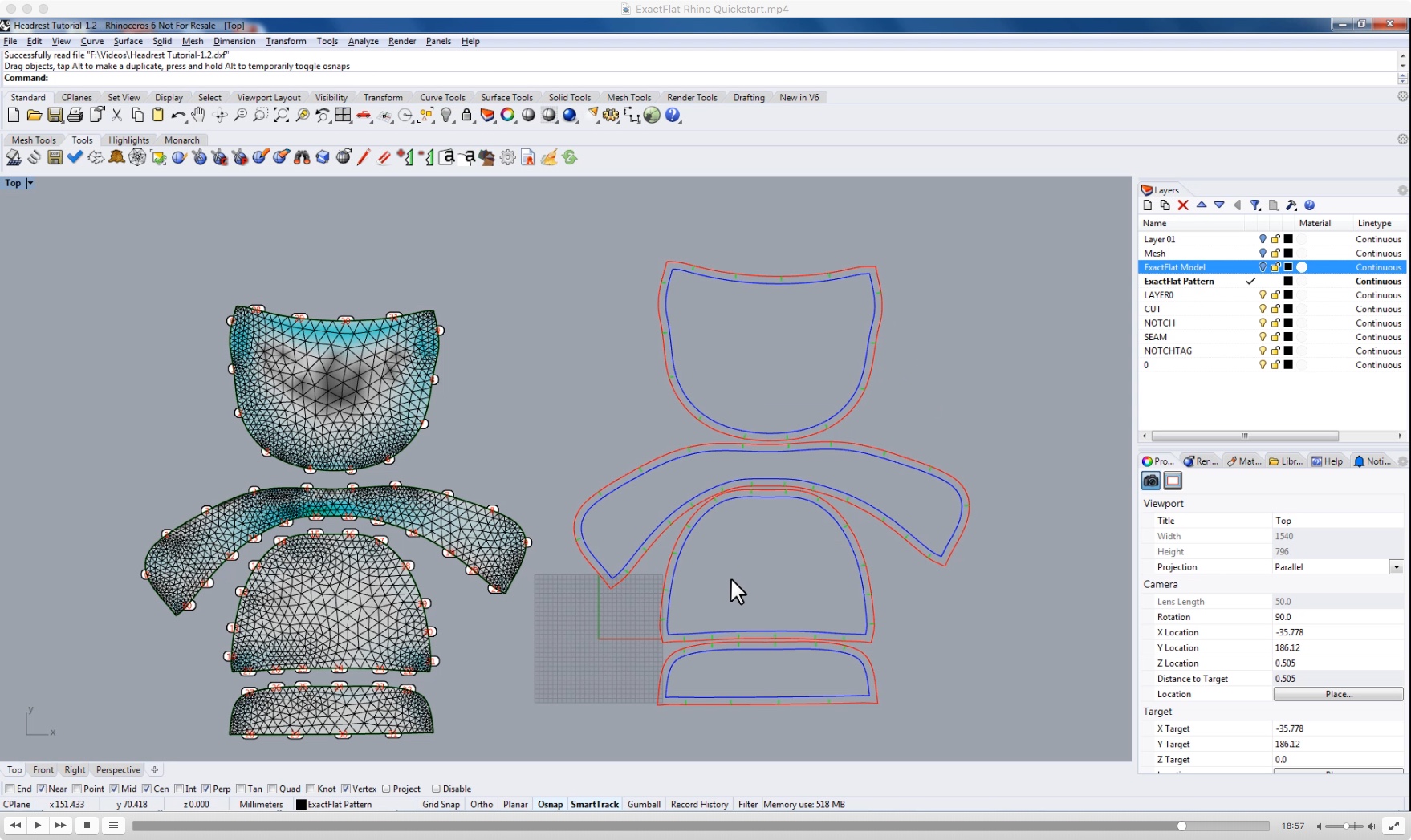

3D to 2D Flattening of an Autmotive Headrest

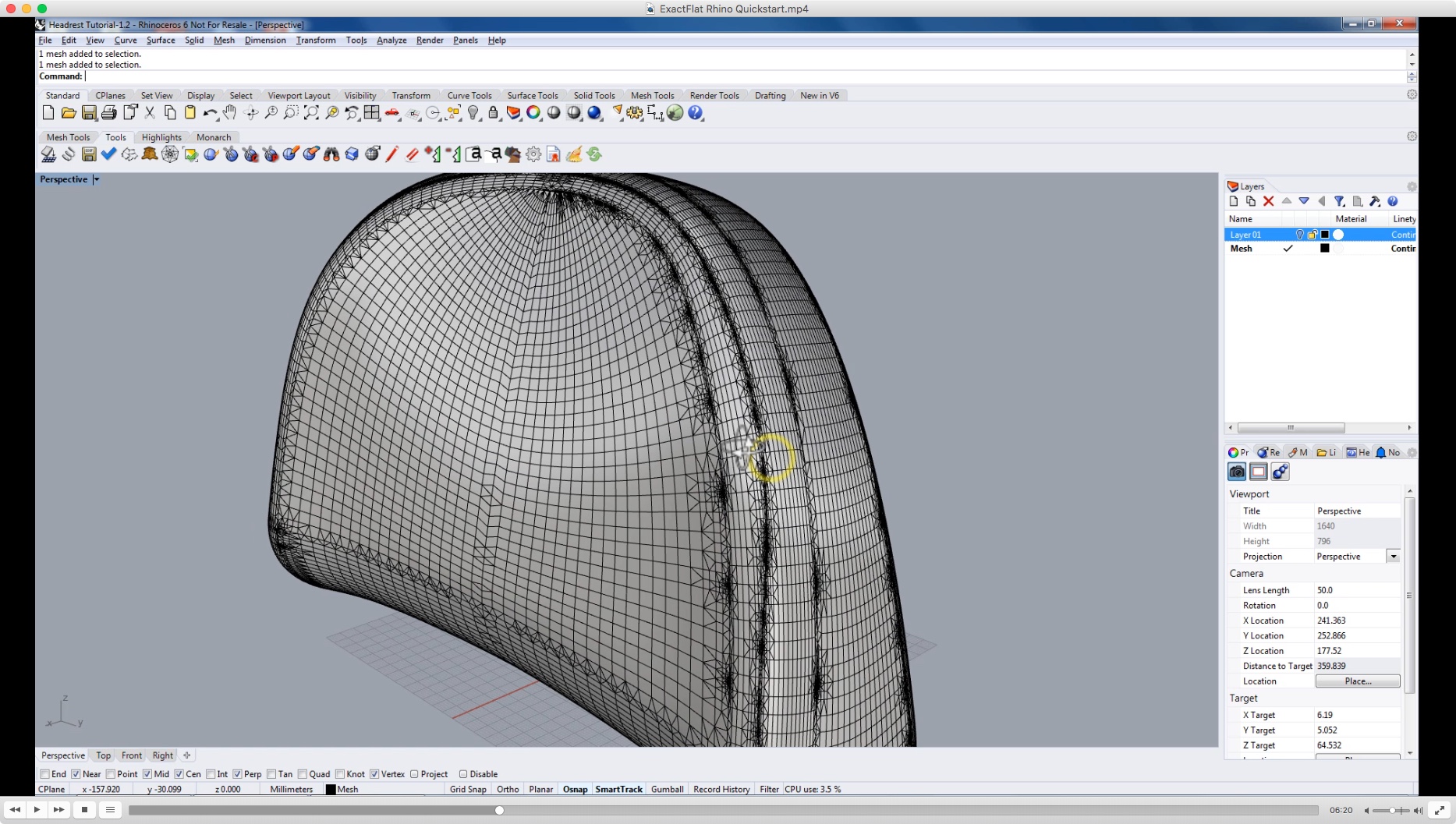

Automotive headrest 3D CAD model for digital pattern making using ExactFlat and Rhino 3D

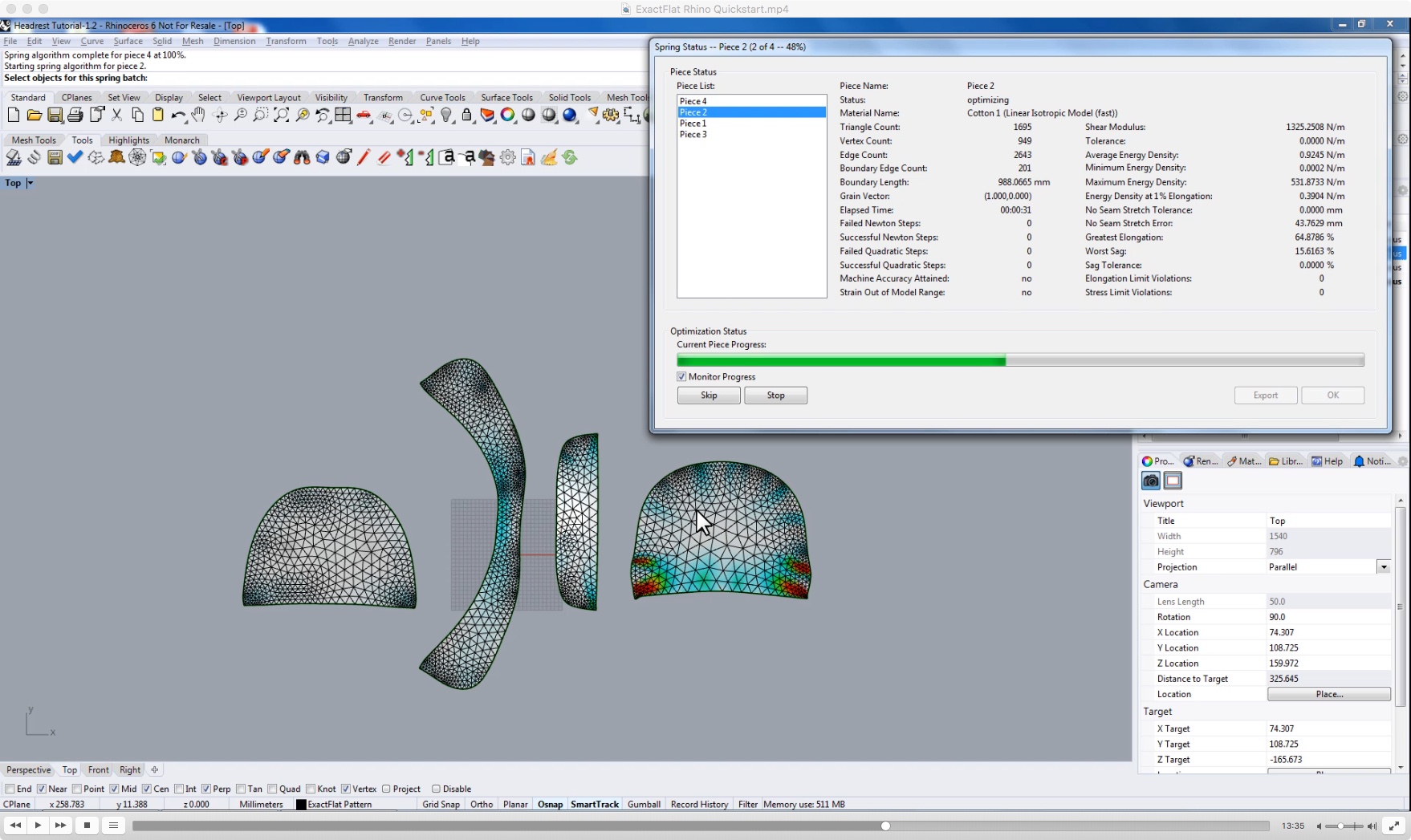

FLAT PATTERNS FOR AUTOMOTIVE HEADREST SHOWING THE EXACTFLAT 3D TO 2D FLATTENER INTERFACE

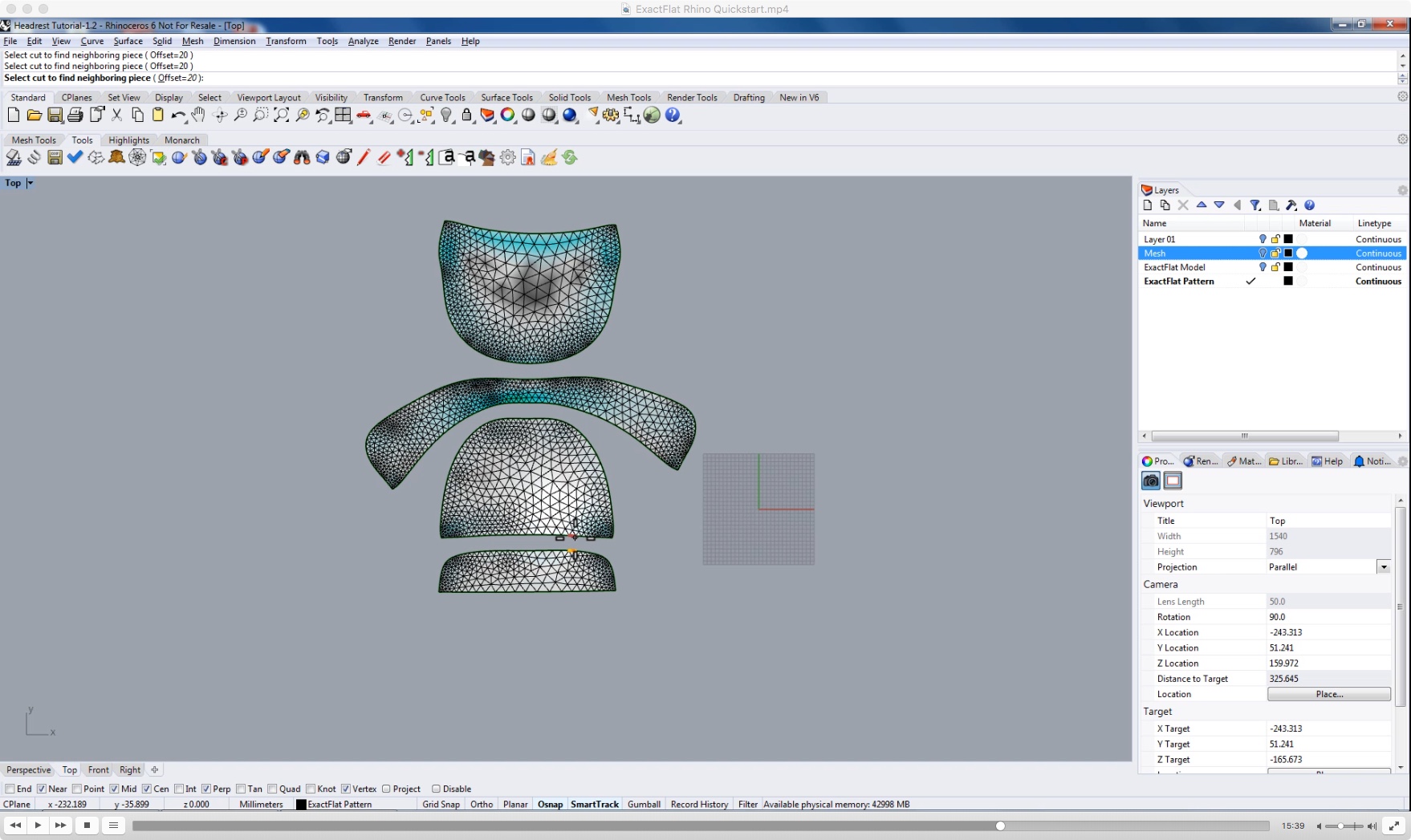

FINAL FLAT PATTERNS FROM 3D MODEL OF AUTOMOTIVE HEADREST SHOW IN EXACTFLAT FOR RHINO 3D

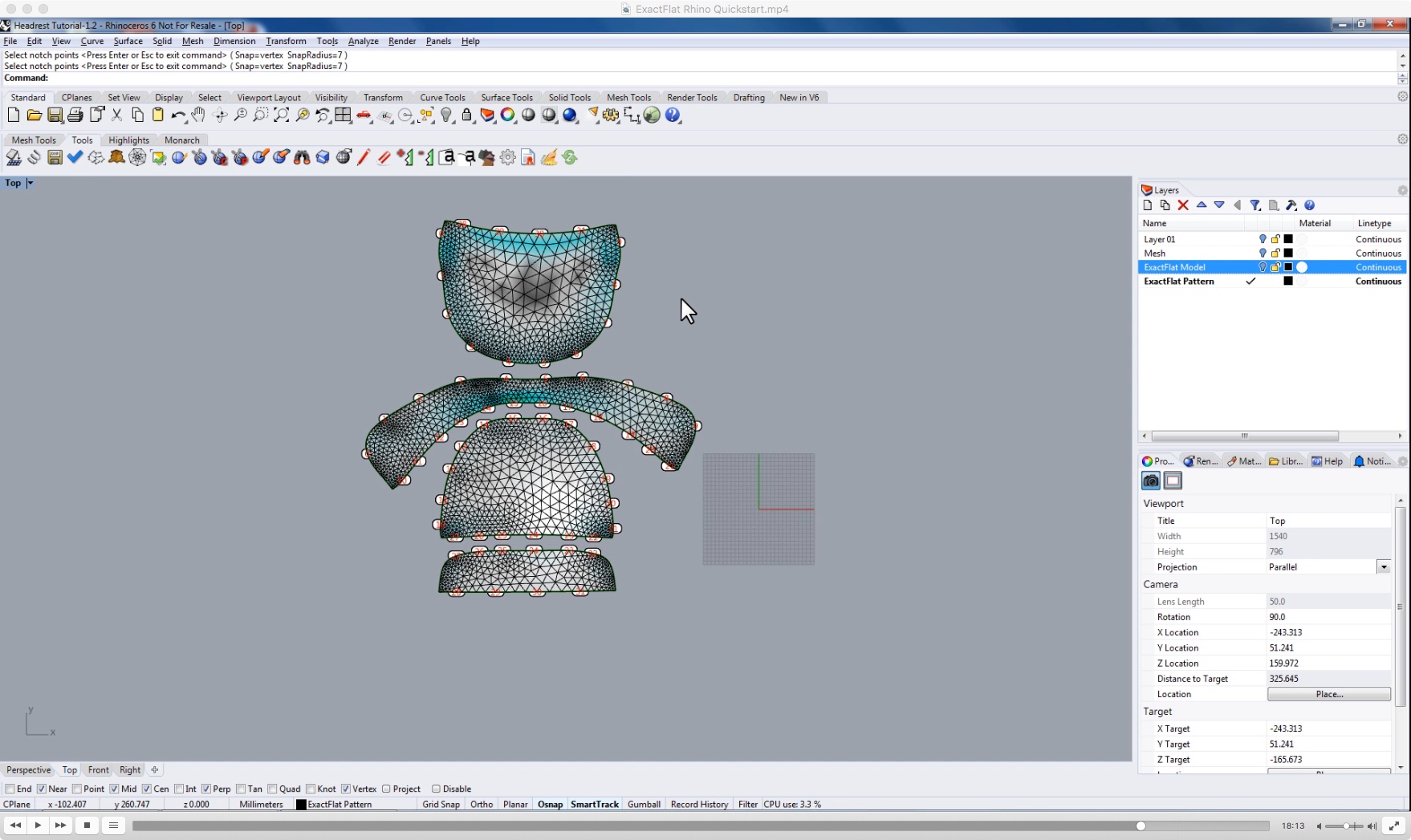

ALIGNMENT NOTCHES FOR 2D FLAT PATTERNS FOR AUTOMOTIVE HEADREST SHOWIN IN EXACTFLAT FOR RHINO 3D

FLAT PATTERNS PLUS DXF CUT FILE WITH SEAM ALLOWANCE FOR AUTOMOTIVE HEADREST SHOWN IN EXACTFLAT FOR RHINO 3D

Video Example of ExactFlat on an Automotive Headrest

The automotive head rest is an idea product for 3D to 2D digital pattern making. This is because their designs originate in 3D CAD. These CAD files are often well suited to 3D to 2D flattening. Also, if the CAD files are not available, the headrest is small enough that it is a suitable for 3D scanning. 3D scanners are easy enough to use and their output is easy enough to process that it makes digital patterning making from scanned data a fast alternative. Check out the video example below for an overview of the 3D CAD to 2D flat pattern process using ExactFlat for Rhino 3D.